Empowering Fabric Manufacturing lines with

Real-time Insight

In the highly competitive manufacturing industry, data is power. Gaining insights and making informed decisions based on comprehensive data analysis can give companies a significant edge. Recognizing this, a leading fabric manufacturer embarked on a journey to revolutionize their data handling practices. They sought to implement a system that would not only provide deeper insights but also help streamline their production processes and optimize efficiency.

The Challenge

- This company wanted to gain deeper insights into their data and make more informed decisions. They needed a system that could filter and view data based on specific parameters such as operator, production period, product code, fault code, and workgroup.

- They also wanted to calculate the total fabric meterage for each product code. This information is crucial for inventory management, cost analysis, and production planning.

The Solution

- Connectivity and Hardware Integration

By connecting our system to the encoder, we accurately measured the length of each fabric roll. The encoder provided precise measurements, ensuring that the total fabric meterage for each product code was calculated correctly.

We also integrated start and finish buttons to reset the encoders, capturing the exact moments when fabric roll production began and ended. This provided accurate data for tracking.

- Tracking Solutions

Each fabric roll was assigned a unique product code, which was scanned at the beginning of production. This product code became the identifier for all subsequent data associated with that particular roll. Additional information, such as batch number, production date, and shift, could also be linked to the product code for detailed tracking.

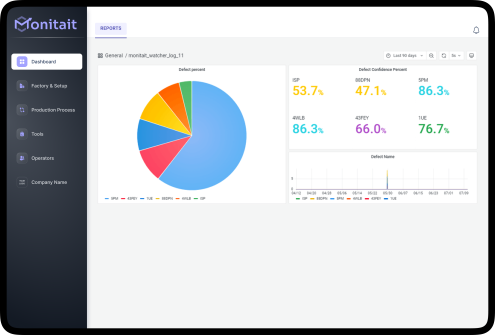

- Advanced Filtering and Exporting Reports

Our system provided filters for roll reports based on various parameters, including operator, workgroup, device number, product code, and timeframe. This allowed for targeted analysis and problem-solving. For example, identifying if a specific operator or workgroup consistently had higher defect rates or if a particular device needed maintenance.

- Management Reports

Customizable management reports were made available, providing insights into key performance indicators such as total production, downtime, defect rates, and fabric meterage per product code. These reports could be generated for specific periods, helping managers make data-driven decisions and identify areas for optimization.

Results and Achievements

The adoption of AI fabric inspection yields substantial outcomes for fabric manufacturers:

1. Improved Data Insights:

With the implementation of our real-time data analysis system, the company gained deeper insights into its production processes and inventory management.

2. Enhanced Operational Efficiency:

By streamlining processes, automating data collection, and minimizing manual interventions, they reduced lead times and optimized resource utilization.

3. Reduced Waste and Costs:

Minimizing machine downtime enabled the company to reduce waste and associated costs. The early identification of issues allowed for prompt corrective actions and preventing costly mistakes.

%

Accuracy

%

Improvement of Efficiency

Reduce Downtimes

%

Conclusion

Our collaboration with this fabric manufacturer company has yielded remarkable results, leveraging AI and data analysis to transform their operations. By using Monitait, our web-based production monitoring software, they optimized production processes and enhanced operational efficiency. This success showcases the power of data insights in driving operational excellence and positioning the company for future growth.

I can confidently say that Monitait has been a game-changer. It has empowered us to identify and address the bottlenecks that were holding us back.

Production Manager

@Fabric Manufacturing Company